TYPICAL APPLICATIONS

Over 60 Million Parts Succesfully Repaired By LAWS

Our Successful Repairs Include:

SilverCrest

LEAP

GE90

GenX

CF6 HPT Stg 1&2

CF6 Stg 1- HPC (All Variations)

CFM-56 HPT Stg 1

CFM-56 HPC Stg 1-14

CFM-56 LPT

PW4000 HPT & LPT SX CMSX

PW4000 Shroud Segment

PW4000 HPT Stg 1 & 2 root throttle plate

PW2000 LPT, GP7000 LPT

PW2000 HPC Titanium Stg 10

PW PT6 IBR Blisk

V2500 HPC & HPT (All Stages)

Rolls Royce Trent 1000 Gear Box

Rolls Royce Trent 500, 700, 800

HPC (All Stages & Models)

GE T64 Stage 1 NGV

GE Shaft Seals T700 & T800

Rolls Royce – BR 710/715,

Combustor, Vanes, Seals

GE 90 (All Stages)

Over 60 Million Parts Succesfully Repaired By LAWS

Our Successful Repairs Include:

SilverCrest

LEAP

GE90

GenX

CF6 HPT Stg 1&2

CF6 Stg 1- HPC (All Variations)

CFM-56 HPT Stg 1

CFM-56 HPC Stg 1-14

CFM-56 LPT

PW4000 HPT & LPT SX CMSX

PW4000 Shroud Segment

PW4000 HPT Stg 1 & 2 root throttle plate

PW2000 LPT, GP7000 LPT

PW2000 HPC Titanium Stg 10

PW PT6 IBR Blisk

V2500 HPC & HPT (All Stages)

Rolls Royce Trent 1000 Gear Box

Rolls Royce Trent 500, 700, 800

HPC (All Stages & Models)

GE T64 Stage 1 NGV

GE Shaft Seals T700 & T800

Rolls Royce – BR 710/715,

Combustor, Vanes, Seals

GE 90 (All Stages)

Induction Welding Station (Optional)

The optional induction welding station is designed to pre-heat components to be welded at elevated temperatures. The induction station comes complete with a custom-designed coil to ensure uniform heating of the component, argon purging to avoid oxidation as well as programmable heating controls.

Induction Welding Station (Optional)

The optional induction welding station is designed to pre-heat components to be welded at elevated temperatures. The induction station comes complete with a custom-designed coil to ensure uniform heating of the component, argon purging to avoid oxidation as well as programmable heating controls.

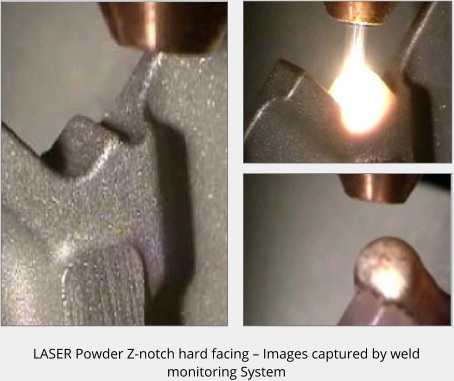

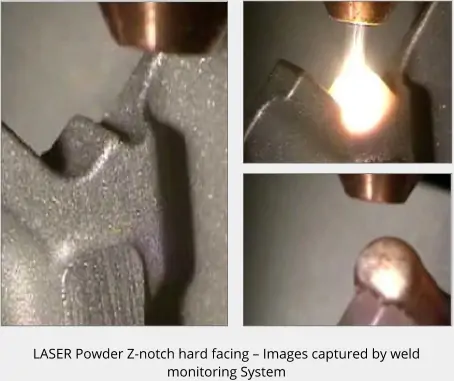

Weld Monitoring System

The Liburdi weld monitoring system provides a full HD digital high dynamic range camera with specially designed weld lenses for ARC and LASER processes. The live view has user definable profiles to provide the operator with the tools to optimize images for both setup and welding operations.

The real time weld monitor is equipped with a suite of tools to allow for operator setup and part tracking utilizing overlay and adaptive vision. For ease of operation and quality control purposes, all key process parameters are displayed and recorded.

Weld Monitoring System

The Liburdi weld monitoring system provides a full HD digital high dynamic range camera with specially designed weld lenses for ARC and LASER processes. The live view has user definable profiles to provide the operator with the tools to optimize images for both setup and welding operations.

The real time weld monitor is equipped with a suite of tools to allow for operator setup and part tracking utilizing overlay and adaptive vision. For ease of operation and quality control purposes, all key process parameters are displayed and recorded.

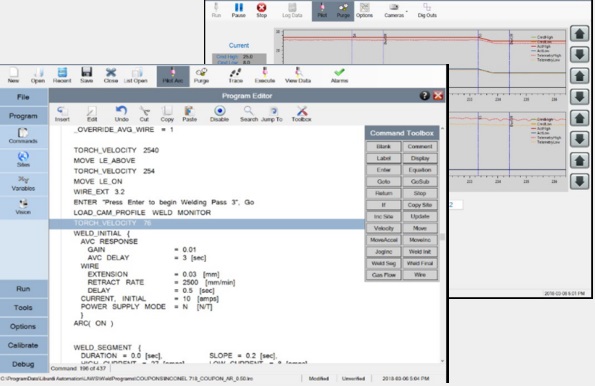

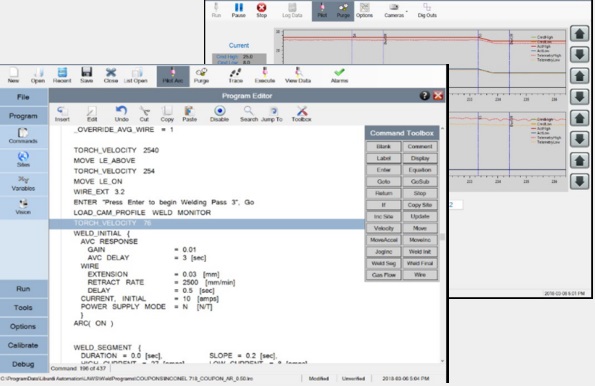

LAWS™ 4.0 Software

All of the LAWS™, (Liburdi Automated Welding System), series of robots use a common control system. This system, called LAWS™, is a Windows™ application specially designed for automated welding.

Liburdi user interface uses a simple and intuitive touch screen for navigation. The operator selects commands from well-organized drop-down menus, simply touches the numbers he wishes to change allowing welding schedules to be quickly generated or modified.

LAWS™ 4.0 Software

All of the LAWS™, (Liburdi Automated Welding System), series of robots use a common control system. This system, called LAWS™, is a Windows™ application specially designed for automated welding.

Liburdi user interface uses a simple and intuitive touch screen for navigation. The operator selects commands from well-organized drop-down menus, simply touches the numbers he wishes to change allowing welding schedules to be quickly generated or modified.

LAWS 750