- High precision welding system with 3-5 axes; expandable with fully-digital controls.

- Full synchronization of current and wire feed to produce a high frequency "dabbing" motion during welding. This results in superior weld quality on a variety of heat sensitive alloys.

- Multi-process capable, using both Gas Tungsten Arc Welding (GTAW) and Plasma Arc Welding (PAW) with a quick-change over feature. Minimal downtime.

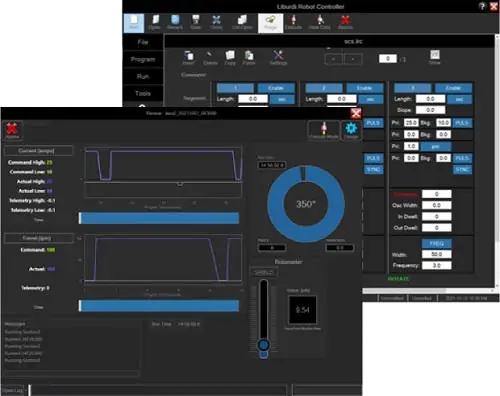

- User friendly HMI with real-time parameter control and key process data logging.

LAWS Lite Software

- LAWS Lite offers structured preset weld program structure

- Fully coordinated if necessary (X, Z and optionally BOOM)

- Uses all the LAWS process features (AVC, Oscillation)

- Optionally buy all LAWS extended features (thermal camera, seam tracking, vision)

- Integrated Liburdi weld monitoring camera

Operator Control Station

- Multi language interface.

- Multi process automatic switch over for GTAW and PAW

- 50-200A GTAW and PAW configurable power supplies

- Full digital mass flow controller gas box