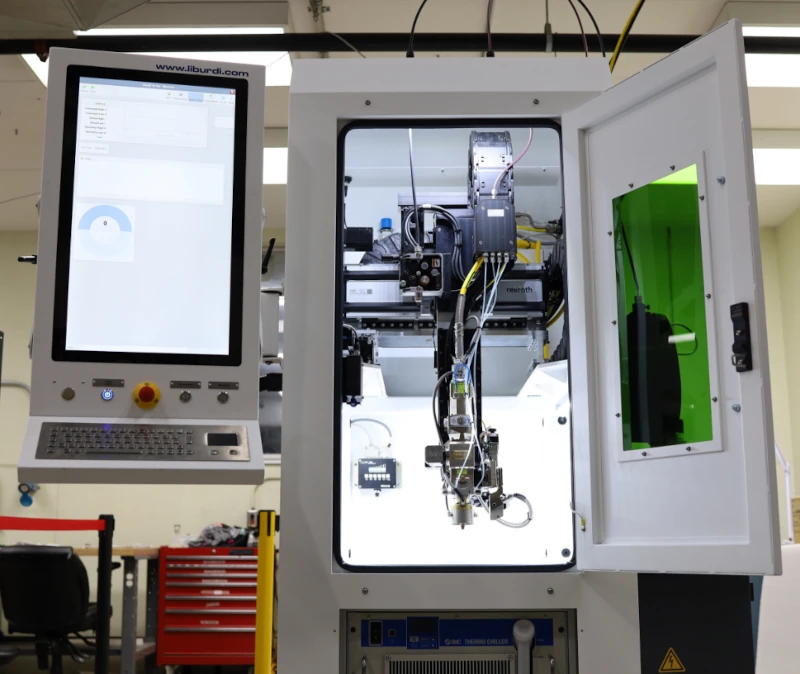

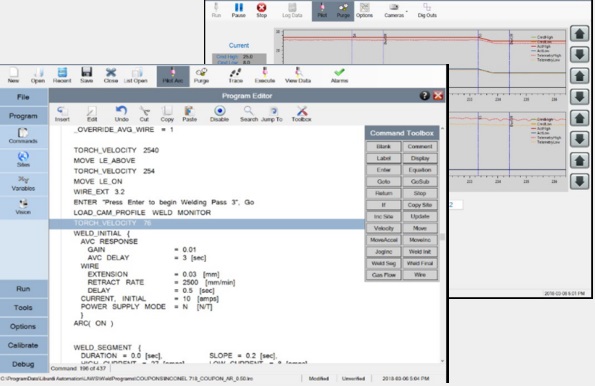

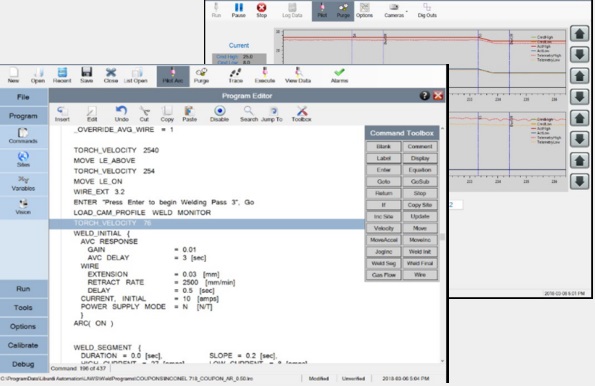

All of the LAWS™, (Liburdi Automated Welding System), series of robots use a common control system. This system, called LAWS™, is a Windows™ application specially designed for automated welding.

Liburdi user interface uses a simple and intuitive touch screen for navigation. The operator selects commands from well-organized drop-down menus, simply touches the numbers he wishes to change allowing welding schedules to be quickly generated or modified.

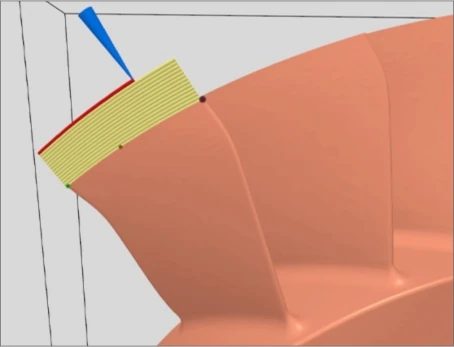

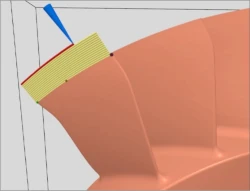

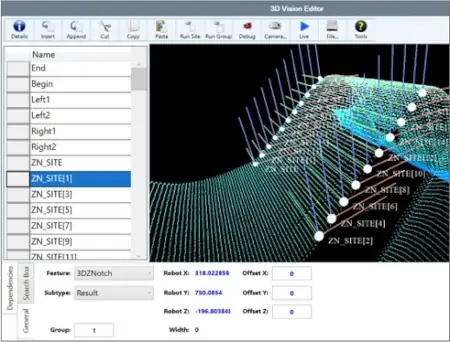

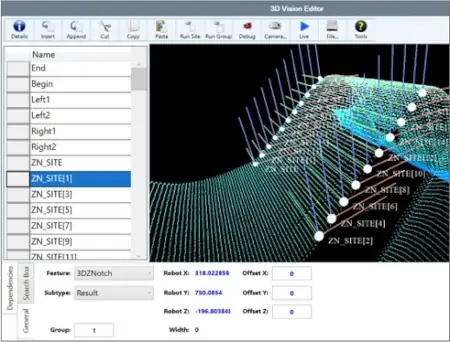

Liburdi's adaptive 3D vision system constructs a point cloud model to accurately generate the robot path within the 5 axis work platform.

The 3D scanning option allows the LAWS systems the ability to build up complex geometries from a scanned master component. Using 3D point cloud weld path generation over traditional method of multiple camera images simplifies the site finding process.

The 3D scanning option allows the LAWS systems the ability to build up complex geometries from a scanned master component. Using 3D point cloud weld path generation over traditional method of multiple camera images simplifies the site finding process.

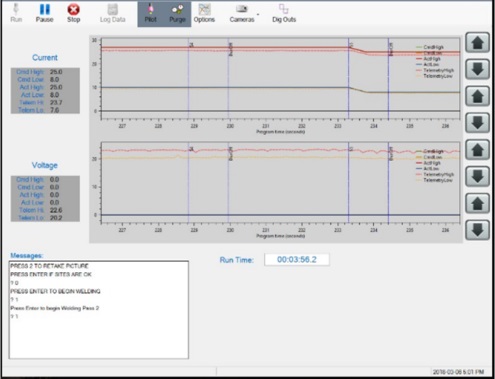

From part tracking to weld monitoring, the LAWS1000 is designed to be intelligible and intuitive, with the capability of adapting to part variances. The Liburdi Robotic Controller provides real-time data logging and graphical display of all welding parameters, as well as operator feedback and guidance, customized to your application.

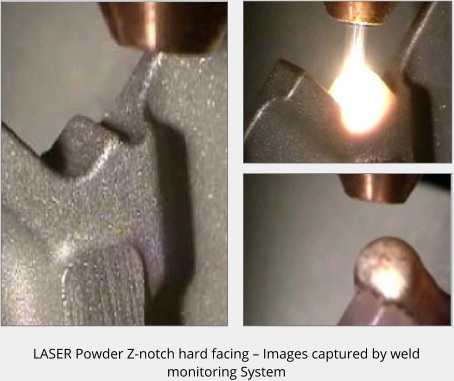

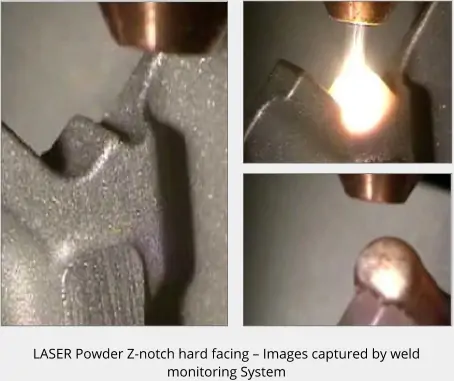

The robust design of dual-driven gantry axes with absolute encoders ensure the finest motion accuracy and repeatability. The operator may view the welding process live via the HD weld monitoring system; a feature that can also be used to record the welding process for logging and training references. Contact us to learn more about the LAWS1000’s standard and advanced features that will benefit your welding application.

From part tracking to weld monitoring, the LAWS1000 is designed to be intelligible and intuitive, with the capability of adapting to part variances. The Liburdi Robotic Controller provides real-time data logging and graphical display of all welding parameters, as well as operator feedback and guidance, customized to your application.

The robust design of dual-driven gantry axes with absolute encoders ensure the finest motion accuracy and repeatability. The operator may view the welding process live via the HD weld monitoring system; a feature that can also be used to record the welding process for logging and training references. Contact us to learn more about the LAWS1000’s standard and advanced features that will benefit your welding application.