TYPICAL APPLICATIONS

Over 60 Million Parts Succesfully Repaired By LAWS

Our Successful Repairs Include:

SilverCrest

LEAP

GE90

GenX

CF6 HPT Stg 1&2

CF6 Stg 1- HPC (All Variations)

CFM-56 HPT Stg 1

CFM-56 HPC Stg 1-14

CFM-56 LPT

PW4000 HPT & LPT SX CMSX

PW4000 Shroud Segment

PW4000 HPT Stg 1 & 2 root throttle plate

PW2000 LPT, GP7000 LPT

PW2000 HPC Titanium Stg 10

PW PT6 IBR Blisk

V2500 HPC & HPT (All Stages)

Rolls Royce Trent 1000 Gear Box

Rolls Royce Trent 500, 700, 800

HPC (All Stages & Models)

GE T64 Stage 1 NGV

GE Shaft Seals T700 & T800

Rolls Royce – BR 710/715,

Combustor, Vanes, Seals

GE 90 (All Stages)

Over 60 Million Parts Succesfully Repaired By LAWS

Our Successful Repairs Include:

SilverCrest

LEAP

GE90

GenX

CF6 HPT Stg 1&2

CF6 Stg 1- HPC (All Variations)

CFM-56 HPT Stg 1

CFM-56 HPC Stg 1-14

CFM-56 LPT

PW4000 HPT & LPT SX CMSX

PW4000 Shroud Segment

PW4000 HPT Stg 1 & 2 root throttle plate

PW2000 LPT, GP7000 LPT

PW2000 HPC Titanium Stg 10

PW PT6 IBR Blisk

V2500 HPC & HPT (All Stages)

Rolls Royce Trent 1000 Gear Box

Rolls Royce Trent 500, 700, 800

HPC (All Stages & Models)

GE T64 Stage 1 NGV

GE Shaft Seals T700 & T800

Rolls Royce – BR 710/715,

Combustor, Vanes, Seals

GE 90 (All Stages)

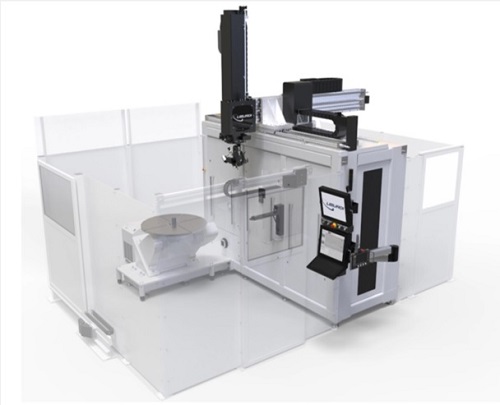

Machine Guarding

Liburdi machine guards are built to the latest CE directive and applicable standards. Full safety cell monitored digital interlocked doors, auto darkening viewing windows.

Ergonomic designs for both operators and loading of large components

All LASER systems built to Class 1 ANSI Z136 Standards

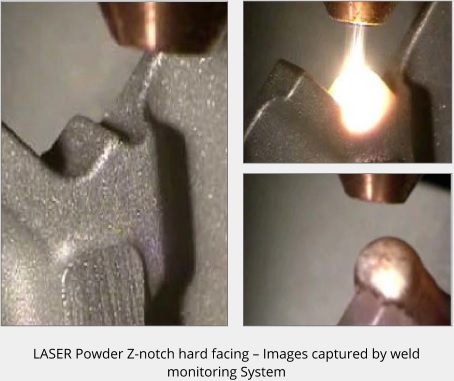

Weld Monitoring System

Liburdi welding monitoring system provides a HD color micro-camera with special lenses and filters on an adjustable bracket that is placed near the weld. The zoomed-in live view that it provides is shown on the computer monitor during a weld, making it easy to see the weld, even if the part is obstructed. This image can also be stored to the hard drive in MPEG format for quality control records

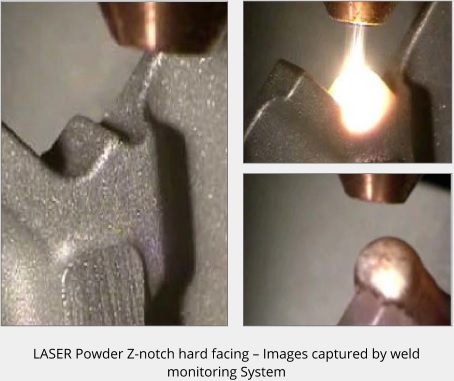

Weld Monitoring System

Liburdi welding monitoring system provides a HD color micro-camera with special lenses and filters on an adjustable bracket that is placed near the weld. The zoomed-in live view that it provides is shown on the computer monitor during a weld, making it easy to see the weld, even if the part is obstructed. This image can also be stored to the hard drive in MPEG format for quality control records

Configurable Designs

The LAWS 5000 can be configured to include the following options:

- TIG

- Plasma

- Pulsed or Continuous LASER with wire or powder filler material

- Multiple axes configurations:

- X, Y, Z, W, R, T, Θ

LAWS 5000